Continuous Mixers

Continuous Mixing technology represents a significant advancement in the field of industrial mixing. By integrating storage, feeding and metering, mixing of the ingredients and further processing of the mixture into a continuous and uninterrupted process, a high degree of consistency and uniformity of the end product is guaranteed.

The efficiency of Continuous Mixing technology lies in its ability to streamline the entire mixing process. Unlike batch mixing, which handles each step as a separate operation and can be time-consuming when processing large quantities, Continuous Mixing operates on a constant flow basis. This not only saves time but also enhances the accuracy of ingredient incorporation, leading to a high-quality end product.

Furthermore, the adoption of Continuous Mixers can lead to substantial cost savings for industrial processes. By reducing the need for multiple pieces of equipment and minimising energy consumption, companies can lower both capital and operational expenses. Additionally, the compact nature of Continuous Mixing systems means they occupy less space, allowing for more efficient use of manufacturing facilities and potentially reducing the overall footprint of the mixing operation.

RELATED PRODUCTS

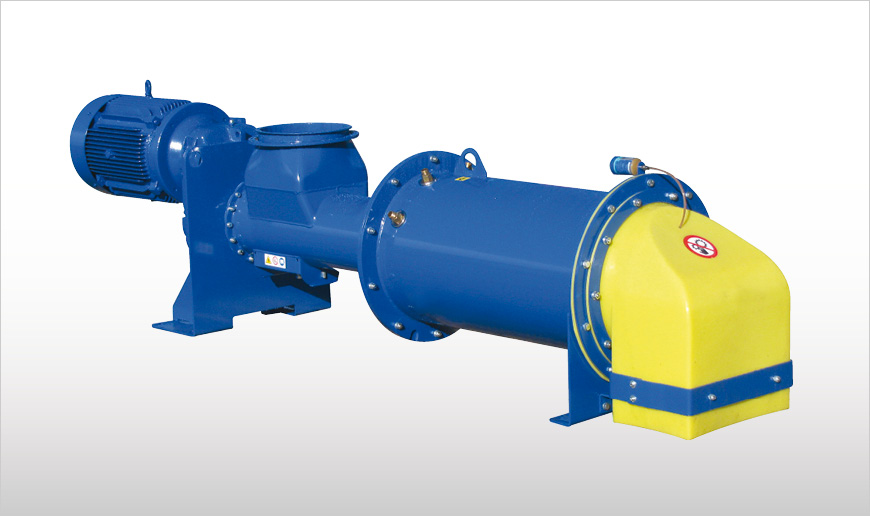

Continuous Single Shaft Industrial Mixers WAH

The WAH Continuous Single Shaft Industrial Mixer is the ideal machine to obtain highest quality mixtures. Mixing with WAH is quick though gentle. Thousands of mixers supplied in the last three decades by MAP all over the world stand for total reliability and durability.

Read moreContinuous Twin Shaft Paddle Industrial Mixers MESC-MESC-UM

The MESC-type Twin Shaft Paddle Industrial Mixer (MESC-UM as conditioner with liquid injection) is among the most efficient yet economic mixer types when it comes to conditioning dust or inerting sludge.

Read moreDUSTFIX Industrial Dust Conditioners

In terms of functionality and cost-effectiveness, the DUSTFIX Industrial Dust Conditioner is the optimal solution for evacuating, conditioning, and disposing of dust across various industries. Its advanced technical features, innovative design, and exceptionally short processing time ensure dust-free discharge onto open trucks or belt conveyors.

Read moreWETDUST Industrial Dust Conditioners

In terms of function and economy, the WETDUST Industrial Dust Conditioner is the ideal machine for evacuating, conditioning and disposal of industrial dust. Due to its particular technical features, its innovative design and extremely short processing time, WETDUST enables dust-free discharging on open trucks or belt conveyors.

Read moreCLAYGRAN Industrial Dust Conditioners for Ceramic Dust

In terms of function and economy, the CLAYGRAN Industrial Dust Conditioner is the ideal machine for the evacuation, conditioning and disposal of industrial ceramic dusts. Due to its particular technical features, its innovative design, and extremely short processing time, CLAYGRAN enables dust-free discharging on open trucks or belt conveyors.

Read moreWAMGROUP®

Shared Values, Trusted Choice.