INDUSTRIAL MIXERS FOR CHEMICALS PROCESSING

Products manufactured on MAP mixers in the chemical industry

Industrial Mixers for Processing of Fertiliser, Pesticides, Agricultural Solvents, Plant Care

Industrial Mixers for Processing of Brake Pad Friction Linings

Industrial Mixers for Processing of Detergents, Soaps, Toothpastes, Cleaning Agents

Industrial Mixers for Processing of Pigments, Dyes, Paint Powders, Additives, Fixing Agents

Further products manufactured on MAP mixers in the chemical industry

Industrial Mixers for Processing of Crushed Raw Materials

Industrial Mixers for Processing of Various Dry Powder Mixtures

Industrial Mixers for Processing of Detergents, Wood, Ligno Substances, Resins

REFERENCES FOR CHEMICALS PROCESSING MIXERS

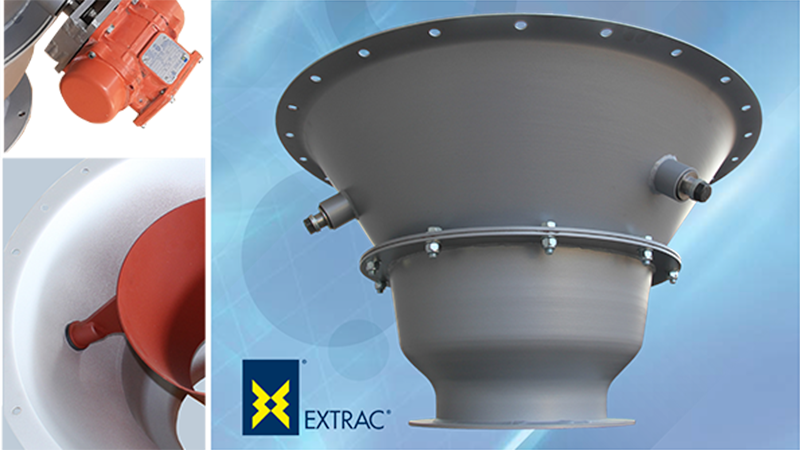

Related Products

BATCH MIXERS

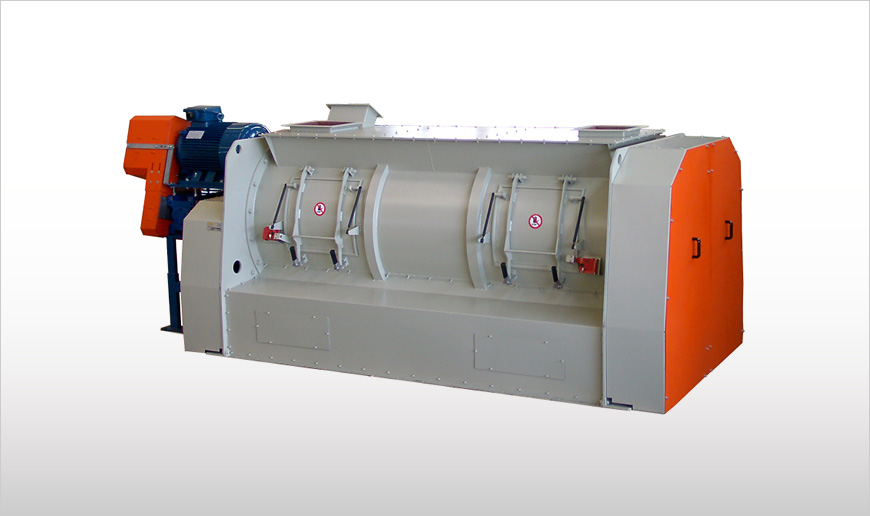

Batch-Type Single Shaft Industrial Mixers WBH

The WBH Batch-Type Single Shaft Industrial Mixer is the ideal machine to obtain highest quality mixtures in perfectly reproducible batches. In the last three decades MAP has supplied thousands of mixers to a large variety of industries worldwide. Mixing tests for customers are performed in the Group’s own laboratories in currently more than fifteen countries.

Read moreBatch-Type Single Shaft Industrial Mixers with Bomb-Bay Discharge WBHP - WBHT

In addition to the features of standard WBH industrial mixers, the WBHP and WBHT-type ensure instant product discharge with residue of less than 0.1% depending on the product mixed. A bomb-bay discharge is mandatory where discharge time has to be reduced to the minimum.

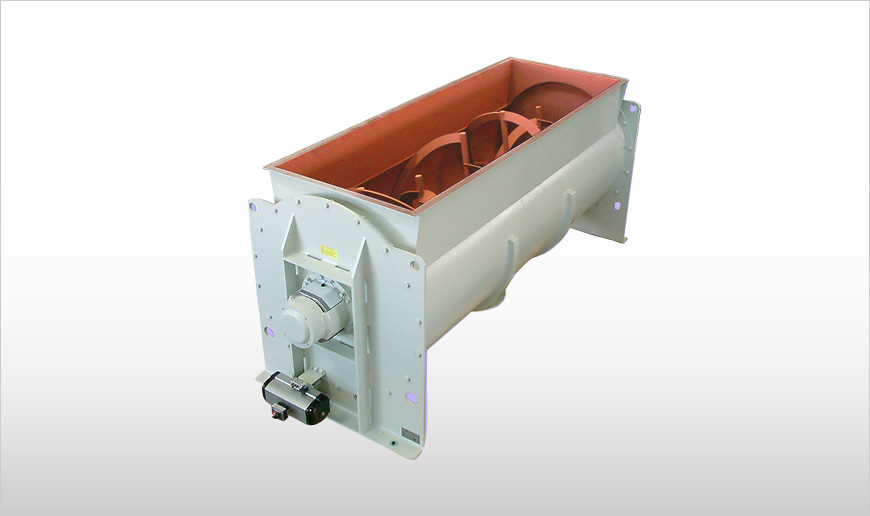

Single-Shaft Industrial Ribbon Blenders WBR

WBR Industrial Ribbon Blenders are the ideal solution to meet the requirements of the market in terms of quality, maintenance and mixing technology. Thanks to the use of proven standard components, MAP® is able to offer an attractive price without compromising on quality.

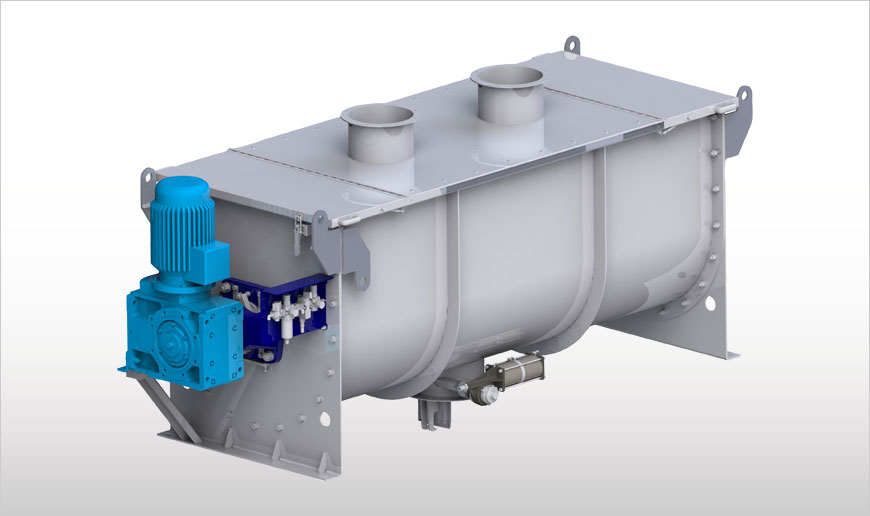

Read moreTubular Batch-Type Industrial Ribbon Blenders WBN

The WBN Batch-Type Industrial Ribbon Blender, with its slowly turning single shaft double counter-pitch ribbon screw, is the ideal machine to obtain high quality mixtures with fragile materials, at the same time conserving the physical properties of the product.

CONTINUOUS MIXERS

Continuous Single Shaft Industrial Mixers WAH

The WAH Continuous Single Shaft Industrial Mixer is the ideal machine to obtain highest quality mixtures. Mixing with WAH is quick though gentle. Thousands of mixers supplied in the last three decades by MAP all over the world stand for total reliability and durability.

Read moreContinuous Twin Shaft Paddle Industrial Mixers MESC-MESC-UM

The MESC-type Twin Shaft Paddle Industrial Mixer (MESC-UM as conditioner with liquid injection) is among the most efficient yet economic mixer types when it comes to conditioning dust or inerting sludge.

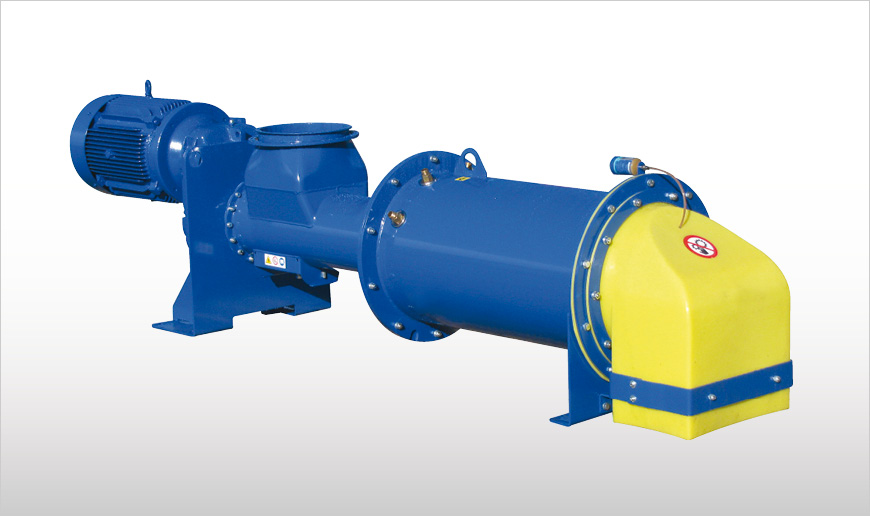

Read moreDUSTFIX Industrial Dust Conditioners

In terms of functionality and cost-effectiveness, the DUSTFIX Industrial Dust Conditioner is the optimal solution for evacuating, conditioning, and disposing of dust across various industries. Its advanced technical features, innovative design, and exceptionally short processing time ensure dust-free discharge onto open trucks or belt conveyors.

Read moreWETDUST Industrial Dust Conditioners

In terms of function and economy, the WETDUST Industrial Dust Conditioner is the ideal machine for evacuating, conditioning and disposal of industrial dust. Due to its particular technical features, its innovative design and extremely short processing time, WETDUST enables dust-free discharging on open trucks or belt conveyors.

Read moreLaboratory Mixers

Laboratory Industrial Mixers MLH

The MLH is a highly efficient, extremely versatile laboratory industrial mixer. In research institutes as well as

in the test facilities of various industries, the MLH mixer offers extensive possibilities for testing

process feasibility. In addition, it is ideally suited for small scale production.

WAMGROUP®

Shared Values, Trusted Choice.

.png?sfvrsn=551ff289_5)